CERAMICS

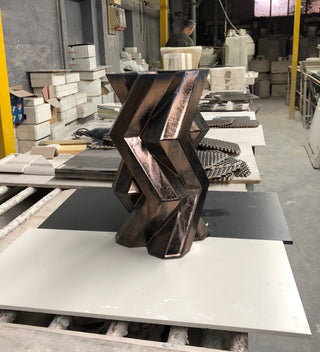

Initially designed Fortress vessels to be electro-formed in copper and eventually I tested them in ceramics. Due to its complex shape and very angular geometry, these are unusual shapes to be manufactured in earthenware ceramics, however they produced extremely good results. The designs are first 3D printed in SLA, from which moulds are made. Into each mould a clay mixture is poured, and once this is dried , it is taken from its mould. The bisque is then first fired in the kiln and then again when the glaze is fired. The glazes are applied by hand before being fired in the oven, producing slightly varied results. That is the beauty of handmade ceramics, each piece is slightly different, as it was painted by hand. Ceramics is basically earth that has been hardened through fire. Firing clay transforms it from its humble, soft beginnings into a new, durable substance: ceramic. It is tough and strong and similar in some ways to stone. Pieces of pottery have survived for thousands of years, all because clay met fire.